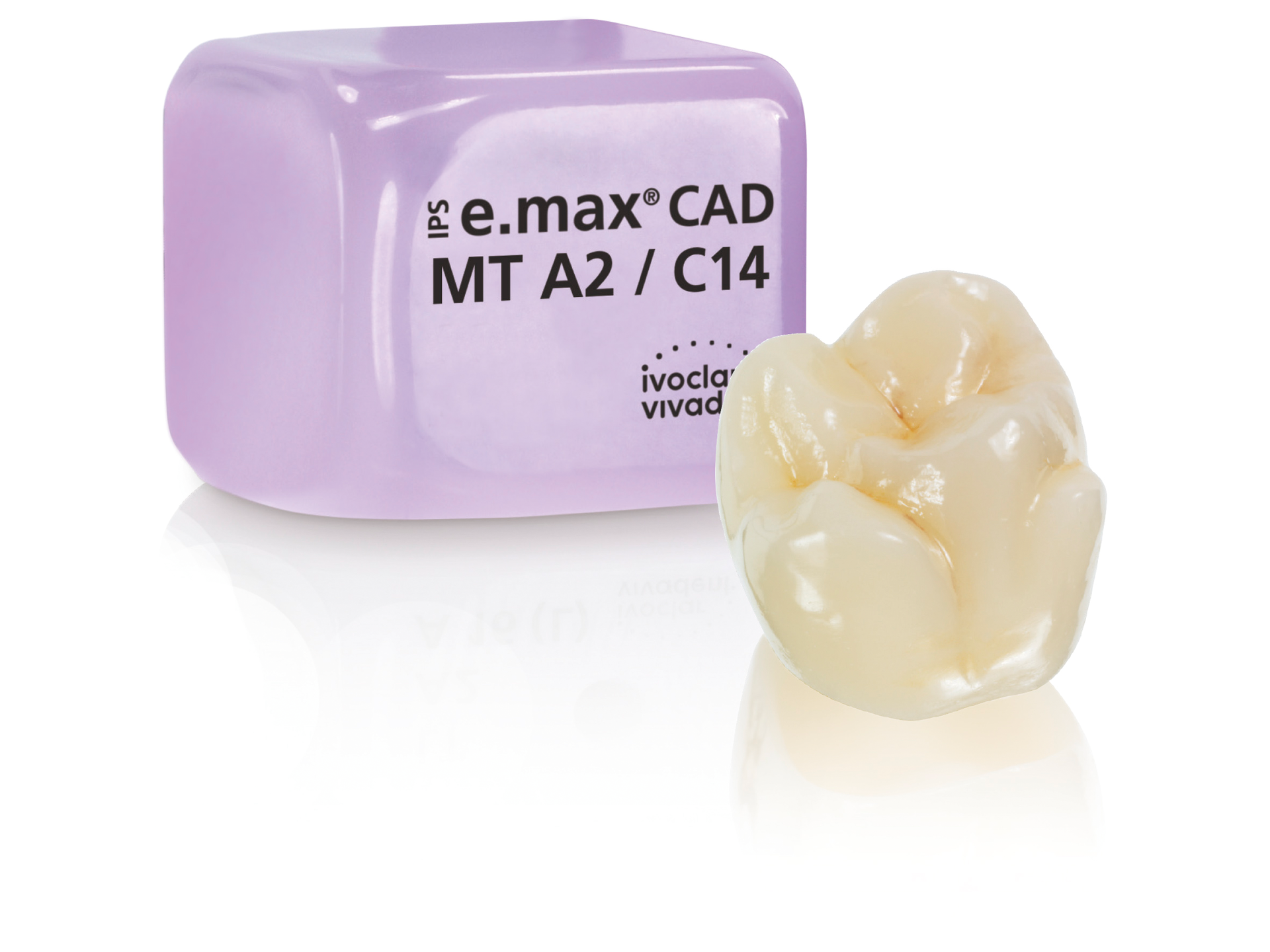

IPS e.max CAD is the world’s best-selling glass-ceramic[1]. It is suitable for the efficient fabrication of full-contour restorations and is known for its versatile applications, comprehensive range of processing options and for its high strength of 530 MPa[2].

IPS e.max CAD is now faster than ever before. Crystallize restorations in just 11:10 minutes with the Programat CS6.[14]

How you benefit:

More than 10 years of ongoing quality testing show that IPS e.max CAD offers a high biaxial flexural strength of 530 MPa[2]. In addition, it shows a high fracture toughness of 2.11 MPa m1/2[3]. This combination is particularly sought after in minimally invasive dentistry.

From crowns, occlusal veneers, and inlays to hybrid abutments – IPS e.max CAD covers a unrivalled scope of applications in CAD/CAM glass-ceramics.

Clinical long-term success and scientifically documented results – the blue block has been on the market since 2005 and has since proven itself clinically[4-6].

With the Programat CS6 combination furnace, IPS e.max CAD restorations can be crystallized faster than ever before with highly-esthetic results.

High esthetic standards are fulfilled due to the four different levels of translucency, the A–D shades and the special Bleach and Impulse shades. The comprehensive range ensures excellent shade match.

IPS e.max CAD restorations can be cemented adhesively, self-adhesively or conventionally, depending on the restoration type[7-9]. This allows you to choose the appropriate cementation method for each clinical situation.

You get a 10-year guarantee on all placed IPS e.max CAD restorations. The IPS e.max Guarantee also applies retroactively for five years to restorations that were permanently placed on 1 July 2015 or later.

- Crowns

- Inlays

- Onlays (z.B. occlusal veneers, partial crowns)

- Veneers

- Three-unit bridges up to the second premolar as the terminal abutment

- Implant-supported hybrid restorations (hybrid abutments, hybrid abutment crowns)

High esthetic standards are fulfilled due to the four different levels of translucency, the A–D shades and the special Bleach and Impulse shades.

Our clinically proven solutions provide you with versatile cementation options – depending on the restoration type, the restorations can be placed using either the adhesive, self-adhesive or conventional luting technique[7-9].

Our well-coordinated range of products offers flexibility in every respect and allows you to choose your preferred processing method – whether you prioritize the most efficient way or highly esthetic results.

The IPS e.max CAD blocks are available in a wide variety of sizes, shades and translucency levels*. This enhances your flexibility, since you always have a suitable block in the desired shade at your disposal. Excellent shade match due to a comprehensive range of shades and translucency levels provides maximum esthetics.

A suitable block for every patient:

-

IPS e.max CAD HT (High Translucency) – the minimally invasive block

-

IPS e.max CAD MT (Medium Translucency) – the bright block

-

IPS e.max CAD LT (Low Translucency) – the versatile block

-

IPS e.max CAD MO (Medium Opacity) – the classical block

-

IPS e.max CAD I (Impulse) – the opalescent block

Given their high translucency, HT blocks are ideally suitable for the fabrication of smaller restorations (e.g. inlays, onlays). Restorations made of HT blocks blend in seamlessly with the natural dentition due to their chameleon effect.

MT blocks demonstrate medium translucency and are used for restorations that require more brightness than HT restorations and more translucency that LT restorations.

Given their low translucency, LT blocks are ideal for the fabrication of larger restorations (e.g. posterior crowns). Restorations made from LT blocks are characterized by their lifelike brightness and chroma.

Given their particular opacity, MO blocks are ideally suitable for the fabrication of frameworks on slightly discoloured preparations. They are primarily used in the dental laboratory.

The Impulse blocks enable the fabrication of restorations with pronounced opalescent properties. The opalescent blocks are available in two versions with different opalescence values. The blocks are suitable for veneers in light tooth shades, which require an opalescent effect.

IPS e.max blocks are equipped with a holder for the authorized CAD/CAM systems of PrograMill (Ivoclar), CEREC® (Dentsply Sirona), PlanMill® (Planmeca) and ceramill® (Amann Girrbach) and N4+® (vhf).

Our materials ideally complement each other. They open up a host of chairside treatment possibilities.

* The range of products varies according to the different CAD/CAM system.

[1] Based on global sales figures.

[2] Average biaxial flexural strength, Outcome after more than 10 years of ongoing quality testing, R&D Ivoclar, Schaan.

[3] Hill T, Tysowsky G, AADR/CADR Annual Meeting: 1672, 2016.

[4] Fasbinder et al., Study report, 2017b.

[5] Rauch A et al., Clin. Oral Investig. 2018, 22, p. 1763-1769.

[6] Boldt J, Spitznagel F. A, Dtsch. Zahnaerztl. Z. 2017, 72 (4), p. 319-325.

[7] Aslan Y. U et al., Eur. J. Prosthodont. Restor. Dent. 2019 (27), p. 131-140.

[8] Lyann S. K et al., J. Adhes. Dent. 2018 (20), p. 261-268.

[9] Schmitz JH, Beani M, J. Adv. Prosthodont. 2016 (115), p. 678 - 683.

[10] The survival rate of monolithic IPS e.max CAD posterior crowns was evaluated with the Kaplan-Meier method. The failure rate refers to technical failures like fracture and chipping, R&D Ivoclar, Schaan.

[11] Çömlěkoglu M. E et al., Clin. Oral Investig. 2017, 2018, 22, 475-486.

[12] Zhang Y et al., Clin. Oral Implant. Res. 2019, 30, 1059-1066.

[13] De Angelis P et al., J. Prosthet. Dent. 2019, 123, 252-256.

[14] Programat CS6, Superspeed crystallization, 11:10 Minuten, IPS e.max CAD HT, MT, LT, IPS e.max CAD Crystall./ Glaze Spray or Self Glaze technique, max. two restorations, R&D Ivoclar, Schaan.

Addtional data on file.

CEREC®, inLab®, PlanMill® and ceramill® are not registered trademarks of Ivoclar Vivadent AG.